Atc Slot Delay Codes

- Atc Slot Delay Codes Code

- Atc Slot Delay Codes Ro Ghoul

- Atc Slot Delay Codes Redeem

- Atc Slot Delay Codes 2020

The Delay Attribution Guide contains a list of delay attribution codes and reasons. The same codes are used in Train Cancellation messages sent on the Train Movements feed.

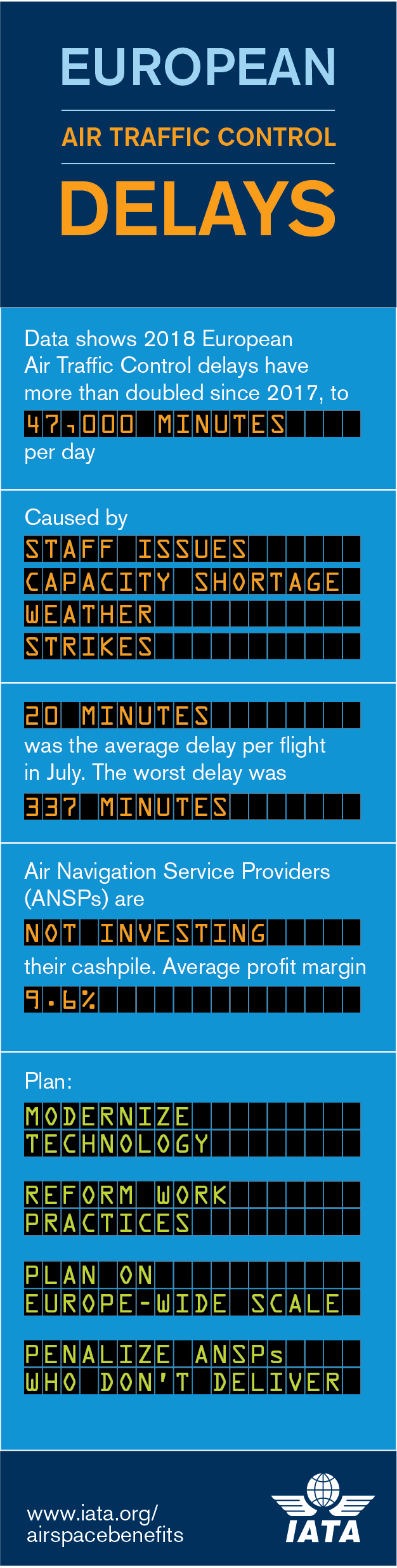

IATA Delay Codes - Delay Codes Starting With 8 (air Traffic Control) Delay Codes Starting With 8 (air Traffic Control) These Codes are used for Air Traffic Control (ATC) Restrictions (81-84) and Airport or Governmental Authorities caused delays. 81: ATC restriction en-route or capacity. FAA assigned take‐off slot due to en route wind conditions, route changes, or spacing requirements. Delays due to a missedslot, charge it to root cause. XB ‐Local Tower ATC: Delay holding for ATC or runway clearance which is withheld by the local FAA or OA tower. Flight crew will be notified.

The codes in use as of September 2020 are listed here for reference.

Codes are grouped in to several sections:

- A* - Freight Terminal Operations Causes

- D* - Holding Codes

- F* - Freight Operating Causes

- I* and J* - Infrastructure causes

- M* and N* - Mechanical or Fleet Engineer Causes

- O* - Network Rail Operating causes

- P* - Planned or excluded delays or cancellations

- Q* - Network Rail Non-Operating causes

- R* - Station Operating Causes

- T* - Passenger Operating causes

- V* - External events – TOC Responsibility

- X* - External events - Network Rail

- Y* - Reactionary Delays

- Z* - Unexplained delays and cancellations

Atc Slot Delay Codes Code

| Code | Cause | Abbreviation |

|---|---|---|

| AA | Waiting acceptance into off Network Rail network Terminal or Yard | ACCEPTANCE |

| AC | Waiting train preparation or completion of TOPS list/RT3973 | TRAIN PREP |

| AD | Off Network Rail network Terminal or Yard staff shortage including reactionary congestion caused by the shortage | WTG STAFF |

| AE | Congestion in off Network Rail network Terminal or Yard | CONGESTION |

| AG | Wagon load incident including adjusting loads or open door | LOAD INCDT |

| AH | Customer or off Network Rail network yard equipment breakdown/reduced capacity | YARD EQUIP |

| AJ | Waiting Customer's traffic including release information and documentation | TRAF DOC |

| AK | Safety incidents and mishaps (e.g. derailments, fire or chemical spill) in off Network Rail network freight yard or terminal (including private sidings, and stations – where it affects FOC services) | YARDSAFETY |

| AX | Failure of off network infrastructure (FOC or private) | OFFNET INF |

| AZ | Other Freight Operating Company cause, to be specified, in off Network Rail network terminals or yards | YARD OTHER |

| DA | Non Technical Fleet Holding Code | HOLD NT FL |

| DB | Train Operations Holding Code | HOLD T-OPS |

| DC | Train Crew Causes Holding Code | HOLD T-CRW |

| DD | Technical Fleet Holding Code | HOLD T FL |

| DE | Station Causes Holding Code | HOLD STN |

| DF | External Causes Holding Code | HOLD EXT |

| DG | Freight Terminal and or Yard Holding Code | HOLD YARD |

| DH | Adhesion and or Autumn Holding Code | HOLD AUTM |

| FA | Dangerous goods incident | DANG GOODS |

| FC | Freight Train Driver error, SPAD, Wrong routing or Missed AWS/DSD | FOC DRIVER |

| FE | Train crew not available including after rest | NO T-CREW |

| FF | FOC Diagramming or Rostering issue | FOC DIAG |

| FG | Driver adhering to company professional driving standards or policy | PRO DRIVER |

| FH | FOC Planning issue (not diagramming or rostering) | FOC PLAN |

| FI | Delay due to incorrect ETCS system or equipment operation by Driver | ETCS DVR |

| FJ | FOC Control decision or directive | FOC CONTRL |

| FK | Train diverted or re-routed at FOC request | DIVERT REQ |

| FL | Train cancelled at FOC request or planned not to run | CANCEL REQ |

| FM | Tail lamp or head lamp out or incorrectly shown | LAMP ISSUE |

| FO | Time lost en-route believed to be Operator cause and information required from Operator (Ops Responsibility) | LIR UNEX |

| FS | Delay due to ETCS/ ERTMS on-board overriding driver command | ETCS O-RDE |

| FW | Late start or yard overtime not explained by Train Operator | LATE START |

| FX | Freight train running at lower class or speed than planned classification or overweight | TRAIN SPEC |

| FZ | Other FOC causes incl. cause to be specified, including mishaps. | FOC OTHER |

| IA | Signal failure (including no fault found) | SIGNAL FLR |

| IB | Points failure (including no fault found) | POINTS FLR |

| IC | Track circuit failure (including no fault found) | TC FAILURE |

| ID | Level crossing faults and failure incl. barrow/foot crossings and crossing treadles | LEVEL XING |

| IE | Signalling functional power supply failure | SIG FUNC PWR |

| IF | Train Describer/Panel/ARS/SSI/TDM/Remote Control failure | PANEL FLR |

| IG | Block failure | BLOCK FLR |

| IH | Power supply and distribution system failure | PWR SUP DIS |

| II | Signalling lineside cable fault | SIG CABLE |

| IJ | AWS/ATP/TPWS/Train Stop/On-track equipment failure | AWS/ATP |

| IK | Telecom equipment failure (including no fault found) | TELECOMS |

| IL | Token equipment failure (including no fault found) | TOKEN FLR |

| IM | Infrastructure Balise Failure (TASS / ETCS / ERTMS) | BALISE FLR |

| IN | HABD/Panchex/WILD/Wheelchex fault, failure or mis-detection | HABD FAULT |

| IP | Points failure caused by snow or frost where heaters are fitted but found to be not turned on, not operative or defective | POINT HEAT |

| IQ | Trackside sign blown down, fallen over, missing, defective, mis-placed | TRACK SIGN |

| IR | Broken/cracked/twisted/buckled/flawed rail | RAIL FLAW |

| IS | Track defects (other than rail defects) inc. fish plates, wet beds etc. | TRACK FLT |

| IT | Rough ride or bumps reported - cause not known or no fault found | TRACK NFF |

| IV | Cutting or embankment earthslip, rock fall or subsidence (not the result of severe weather on the day of failure) | EARTHSLIP |

| IW | Non severe weather - snow/ice/frost affecting infrastructure equipment | INF WEATHR |

| I0 | Telecom equipment legacy radio failure (RETB) | RETB FLR |

| I1 | Overhead line/3rd rail defect | OHL/3 RAIL |

| I2 | AC/DC trip (including no fault or cause found) | AC/DC TRIP |

| I4 | OHLE/3rd rail power supply failure or reduction | SUPPLY FLR |

| I5 | Possession over-run from planned work | OVERRUN |

| I6 | Delays as a result of line blocks / track patrols (including late handback) | LINE BLOCK |

| I7 | Engineer's train late into, from or failed in possession | ENGNRS TRN |

| I8 | Animal Strike or Incursion within the control of Network Rail | ANIMAL |

| I9 | Fires starting on Network Rail Infrastructure | INFRA FIRE |

| JA | TSR speed restrictions for track work outside of the Timetable Planning Rules | TSRNOT EAS |

| JB | Reactionary Delay to ‘P’ coded TSR | TSR REACTN |

| JD | Structures - Bridges/tunnels/buildings/retaining walls/sea defences (not bridge strikes) | STRUCTURES |

| JF | Off track asset defects or issues on the Network Rail network including fencing, gates, walkways, lighting (not due to vandalism or weather or where the asset is part of the station infrastructure) | OFFTRK ASS |

| JG | ESR/TSR due to works not completed or cancelled possession (where restriction did not exist prior to possession) | ESR/TSR |

| JH | Critical Rail Temperature speeds, (other than buckled rails) | HEAT SPEED |

| JK | Flooding not due to exceptional weather | FLOODING |

| JL | Safety related incident caused by maintenance or infrastructure staff oversight or error (not Operations staff) | SAFETY INF |

| JP | Failure to maintain vegetation within network boundaries in accordance with prevailing Network Rail standards, including where signals areobscured and a train strikes branches. | VEGETATION |

| JR | Delay due to RBC issues affecting ETCS / ATO operation (not balise related) | RBC ETCS |

| JS | Condition of Track TSR outside the Timetable Planning Rules | TRACK COND |

| JT | Points failure caused by snow or frost where heaters are not fitted. | NO PNT HTR |

| JX | Miscellaneous items (including litter) causing obstructions, not the result of trespass, vandalism, weather or fallen/thrown from trains | MISC OBJCT |

| J0 | Telecom equipment radio failure (GSM-R) | GSM-R FLR |

| J2 | Network Rail train dispatch equipment failure (including no fault found but excluding telecoms equipment) | TRTS FLR |

| J3 | Axle Counter Failure | AXLE C FLR |

| J4 | Infrastructure Safety Issue Reported by Member of the Public – No Fault Found | MOP NFF |

| J5 | Infrastructure Asset Fault Reported but Proven to be mistaken | MIS REPORT |

| J6 | Lightning strike against unprotected assets | LIGHTNING |

| J7 | ETCS/ ERTMS Equipment Failure (excluding communications link and balises) | ETCS FLR |

| J8 | Damage to infrastructure caused by on-track machine whilst operating in a possession | OTM DAMAGE |

| J9 | Preventative Maintenance to the infrastructure in response to a Remote Condition Monitoring Alert | RCM ALERT |

| MB | Electric loco failure, defect, attention. | ELEC LOCO |

| MC | Diesel loco failure, defect, attention. | DIESL LOCO |

| MD | Other technical failures below the solebar | BELOW SBAR |

| ME | Steam locomotive failure/defect/attention | STEAM LOCO |

| ML | Wagons, coaches and parcel vehicle faults | WAGN/COACH |

| MN | Brake and brake systemsfaults; including wheel flats where no other cause had been identified | BRAKE/WHLS |

| MP | Rail/ wheel interface, adhesion problems (including ice on the running rail) | ADHESION |

| MR | Sanders and scrubber faults | SANDER |

| MS | Planned underpowered or shortformed service and or vehicle, incl. exam set swaps | ALOC STOCK |

| MT | Confirmed train borne safety system faults (not cab based) | SYST FAULT |

| MU | Depot operating problem | DEPOT OPS |

| MV | Engineer’s on-track equipment failure outside possession | ON-TRACK |

| MW | Weather - effect on T&RS equipment | WEATHR FLT |

| MY | Coupler and Coupler system faults | COUPLER |

| M1 | Confirmed Pantograph ADD, shoe beam or associated system faults Incl. positive PANCHEX activations | PANTO/SHOE |

| M2 | Delay due to ATO / ETCS equipment | ETCS |

| M7 | Door and Door system faults | DOORS |

| M8 | Other technical failures above the Solebar | ABOVE SBAR |

| M9 | Reported fleet equipment defect - no fault found | FLEET NFF |

| M0 | Confirmed train cab based safety system fault (including GSM-R) | CAB SAFETY |

| NA | On-train TASS/TILT failure | TASS/TILT |

| OA | Regulation decision made with best endeavours | ENDVR REG |

| OB | Delayed by signaller not applying applicable regulating policy | REGULATION |

| OC | Signaller including mis-routing (not ERTM /ETCS related) | SIGNALLER |

| OD | Delayed as a result of Route Control decision or directive | NR CONTROL |

| OE | Failure to lay Sandite or operate Railhead Conditioning train as programmed | RHC PROG |

| OF | Delay due to incorrect ETCS system or equipment operation by Signaller / Controller | ETCS CTRL |

| OG | Ice on conductor rail/OHLE | ICING |

| OH | ARS / TMS / SARS software problem (excluding scheduling issues and technical failures) | ARS / TMS |

| OJ | Fire in station building or on platform, affecting operators not booked to call at that station | STN FIRE |

| OK | Delay caused by Operating staff oversight, issues or absence (excluding signallers and Control) | OPTG STAFF |

| OL | Signal Box not open during booked hours | BOX CLOSED |

| OM | Technical failure associated with a Railhead Conditioning train | RHC FAIL |

| ON | Delays not properly investigated by Network Rail | MIS-INVEST |

| OQ | Incorrect Simplifier (where produced by Ops staff) | SIMPLIFIER |

| OS | Late start or delays to Railhead Conditioning (RHC) or Ghost Train due to its own activity and not in reaction to another incident. | RHC LATE |

| OT | Operational Safety TSR implemented for sighting issues relating to foot crossings, level crossings or signals (Not vegetation caused) | SIGHT TSR |

| OU | Delays not investigated by Network Rail | NOT INVEST |

| OV | Fire or evacuation due to fire alarm of Network Rail buildings other than stations not due to vandalism | NR FIRE |

| OW | Connections held where the Prime Incident causing delay to the incoming train is a FOC responsibility incident and the next departing service is scheduled to depart less than 60 minutes later than the train being held. | FOC CONECT |

| OZ | Other Network Rail Operating causes | OPTG OTHER |

| PA | Published TSR associated with Planned Engineering Works where time loss is within Engineering Allowance | PLANND ENG |

| PB | Published TSR due to condition of asset (not associated with Engineering Work) where time loss is within Engineering Allowance | PLANND CON |

| PD | System generated cancellation (NOT to be attributed to manually) | SYSTM CANC |

| PF | Planned engineering work where a published diversion/SLW is not provided for in the schedule but where time loss is within Engineering Allowance | DIVRSN SLW |

| PG | Planned cancellation where that cancellation isidentified and agreed prior to 22.00 the day before the schedule runs | PLAND CAPE |

| PJ | Cancellation of a duplicate or erroneous schedule or an identified duplicate, false or erroneous delay (NOT berth off set related) | DUPLICATE |

| PL | Exclusion commercially agreed and documented between Network Rail and Train Operator | AGREED EXC |

| PN | VSTP service delays of under 5 minutes caused by regulation and or time lost in running (VSTP Schedule delay ONLY where that delay causes no reactionary delay) | VSTP DELAY |

| PT | Authorised TRUST reporting anomalies or inaccuraciesrelating to berth off sets | TRUST ANOM |

| QA | WTT Schedule and or LTP process including incorrect simplifiers (where produced by Capacity Planning). | WTT SCHED |

| QB | Planned engineering work- diversion/SLW not timetabled (outside the Timetable Planning Rules.) | DIVRSN/SLW |

| QH | Adhesion problems due to leaf contamination | RAILCONTAM |

| QI | Cautioning due to railhead leaf contamination | CAUTCONTAM |

| QJ | Special working for leaf-fall track circuit operation | LEAVES T/C |

| QM | Train Schedule VAR/STP process including incorrect simplifiers (where produced by Capacity Planning). | STP SCHED |

| QN | VSTP schedule / VSTP process (TSI created schedule) | VSTP SCHED |

| QP | Reactionary Delay to “P” coded Possession | PLND REACT |

| QT | Delay accepted by Network Rail as part of a commercial agreement where no substantive delay reason is identified | COMMERCIAL |

| RB | Passengers joining/alighting | PASSENGERS |

| RC | Pre-booked assistance for a person with reduced mobility joining/alighting | BKD ASSIST |

| RD | Attaching/detaching/Shunter/watering | ATT/DETACH |

| RE | Lift/escalator defect/failure | LIFT/ESC |

| RH | Station evacuated due to fire alarm | FIRE ALARM |

| RI | Waiting connections - not authorised by TOC Control | UNAUTH CON |

| RJ | Special Stop Orders - not authorised by TOC Control | UNAUTH SSO |

| RK | Waiting passenger connections authorised by TOC but out with TOC/Network Rail connection policy | AUTH CON |

| RL | Special Stop Orders authorised by TOC Control (including any delay at point of issue) | AUTH SSO |

| RM | Waiting connections from other transport modes | XTNL CONN |

| RO | Passengers taken ill on platform | PASS ILL |

| RP | Passenger dropped object whilst boarding/alighting from train and train delayed at TOC request | PASS DROP |

| RQ | Un-booked assistance for a person with reduced mobility joining/alighting | UBKD ASST |

| RR | Loading or unloading reserved bicycles | BIKE RSVD |

| RS | Loading or unloading unreserved bicycles | BIKE URSVD |

| RT | Loading excessive luggage | EXCES LUGG |

| RU | Locating lost luggage | LOST LUGG |

| RV | Customer Information System failure | PASS INFO |

| RW | Station flooding (including issues with drains) not the result of weather, where the water has not emanated from Network Rail maintained infrastructure/network | STN FLOOD |

| RX | Station delays as a result of overcrowding due to unplanned events or incidents (e.g result of line or station closure) where causal event is not determined. | UNPL EVENT |

| RY | Mishap - Station operating causes | STN MISHAP |

| RZ | Other Station operating causes | STN OTHER |

| R1 | Incorrect train dispatch by station staff | DISPATCH |

| R2 | Late TRTS given by station staff | LATE TRTS |

| R3 | Station staff unavailable - missing or uncovered | STAFF MSNG |

| R4 | Station staff split responsibility - unable to cover all duties | STAFF DUTY |

| R5 | Station staff error - e.g. wrong announcements, misdirection | STAFF ERR |

| R7 | Station delays as a result of overcrowding due to planned events(e.g.sports fixtures, concerts) | PLND EVENT |

| R8 | Delay at Station believed to be Operator cause and information required from Operator (Station Responsibility) | STN UNEX |

| TA | Train-crew/loco/stock/unit diagram issues | DIAG ISSUE |

| TB | Train cancelled or delayed at Train Operator’s request | TOC REQEST |

| TF | Seat reservation problems | SEAT RESVN |

| TG | Driver | TOC DRIVER |

| TH | (Senior) Conductor/Train Manager | T-MGR/COND |

| TI | Train-crew rostering problem | ROSTERING |

| TJ | Tail lamp or headlamp missing, not lit or wrongly displayed | LAMP ISSUE |

| TK | Train catering staff (including Contractors) | CATERING |

| TM | Connection authorised by TOC but out with connection policy | AUTH CONN |

| TN | Late presentation from the continent | LATE CHUNL |

| TO | Time lost en-route believed to be Operator cause and information required from Operator (Ops Responsibility) | LIR UNEX |

| TP | Special Stop Orders | AUTH SSO |

| TR | Train Operating Company Directive | TOC DIRECT |

| TS | Delay due to incorrect ETCS system or equipment operation by Driver | ETCS DVR |

| TT | Autumn-attribution Neutral Zone delays (See Supplementary Autumn Attribution Guidance) | LF NEUTRAL |

| TW | Driver adhering to company professional driving standards or policy | PRO DRIVER |

| TX | Delays incurred on non-Network Rail running lines or networks including London Underground (except fleet related delays) | OTH NETWK |

| TY | Mishap-Train Operating Company cause | TOC MISHAP |

| TZ | Other Passenger Train Operating Company causes | TOC OTHER |

| T2 | Delay at unstaffed station to non-DOO train | NONDOO STN |

| T3 | Waiting connections from other transport modes | XTNL CONN |

| T4 | Loading Supplies (including catering) | SUPPLIES |

| T8 | Delay at Station believed to be Operator cause and information required from Operator ( Ops Responsibility) | STN UNEX |

| VA | Disorder, drunks or trespass | DISORDER |

| VB | Vandalism and or theft | VANDALISM |

| VC | Fatalities and or injuries sustained whilst on a platform as the result of being struck by a train or falling from a train | FATALITIES |

| VD | Passenger taken ill on train | ILL PASS |

| VE | Ticket irregularities or refusals to pay | TICKET IRR |

| VF | Fire caused by vandalism | VANDL FIRE |

| VG | Police searching train | POLICE-TRN |

| VH | Passenger Communication cord, door egress or emergency train alarm operated | PASS COMM |

| VI | Security alert affecting stations and depots | SEC ALERT |

| VR | Driver adhering to company professional driving standards or policies during severe weather conditions that are not fleet related | PRO DRIVER |

| VW | Severe weather affecting passenger fleet equipment including following company standards/policies or Rule Book instructions | SEV WEATHR |

| VX | External events occurring on the LUL or other non NR running lines | LUL CAUSES |

| VZ | Other passenger or external causes the responsibility of TOC | EXT OTHER |

| V8 | Train striking or being struck by a bird | BIRDSTRIKE |

| XA | Trespass (Including non-intentional) | TRESPASS |

| XB | Vandalism or theft (including the placing of objects on the line) | VANDALS |

| XC | Fatalities or injuries caused by being hit by train (Including non-intentional) | FATALITIES |

| XD | Level Crossing Incidents including misuse and emergency services being prioritised over rail services. | XING INCDT |

| XF | Police searching the line | POLICE-RLY |

| XH | Severe heat affecting infrastructure the responsibility of Network Rail (excluding Heat related speed restrictions) | SEV HEAT |

| XI | Security alert affecting the Network Rail Network (including line blocks taken for emergency services attending an off Network Rail network incident) | SEC ALERT |

| XK | External Power Supply Failure Network Rail Infrastructure | EXTL POWER |

| XL | Fire external to but directly affecting the Network Rail network (including line blocks taken for emergency services attending an incident not directly affecting the Network Rail network) | EXTL FIRES |

| XM | Gas/water mains/overhead power lines | GAS/WATER |

| XN | Road related - excl bridge strikes/level crossing incident | ROAD INCDT |

| XO | External trees, building or structures encroaching or falling onto Network Rail network infrastructure (not due to weather or vandalism) also including aircraft and airport safety or operational related incidents. | EXT OBJECT |

| XP | Bridge Strike | BRIDGE HIT |

| XQ | Swing bridge open for river or canal traffic | BRIDGE OPN |

| XR | Cable vandalism or theft | CABLE VAND |

| XT | Severe snow or ice affecting infrastructure which is the responsibility of Network Rail (including implementation of Key Route Strategy) | SEV SNOW |

| XU | Sunlight on signal or dispatch equipment where all reasonable mitigation has been taken | SUN OBSCUR |

| XV | Fire or evacuation due to fire alarm of Network Rail buildings due to vandalism (not including stations) | VANDL FIRE |

| XW | High winds affecting infrastructure the responsibility of Network Rail including objects on the line due to the effect of weather | HIGH WIND |

| X1 | Visibility in semaphore signalled areas, orspecial working for fog and falling snow implemented by Network Rail – in all signalling areas (including special working for level crossing visibility) | SPL WRKING |

| X2 | Severe flooding beyond that which could be mitigated on Network Rail infrastructure | SEV FLOOD |

| X3 | Lightning Strike – damage to protected systems. | LIGHTNING |

| X4 | Blanket speed restriction or Key Route Strategy implemented for extreme heat or high winds (not snow) in accordance with the Group Standards | KRS / BLKT |

| X8 | Animal Strike or incursion not within the control of Network Rail | EXT ANIMAL |

| X9 | Points failure caused by severe snow or ice where heaters are fitted and working as designed | PNTS SNOW |

| YA | Lost path - regulated for train running less late | REG-ONTIME |

| YB | Lost path - regulated for another later running train | REG-LATE |

| YC | Lost path - following train running less late | FOL-ONTIME |

| YD | Lost path - following another later running train | FOL-LATE |

| YE | Waiting path onto/from single line | WTG S/LINE |

| YG | Regulated in accordance with Regulation Policy | REG INSTRC |

| YI | Late arrival of booked inward stock (inward and outward trains are operated under the same Track Access Contract) | INWD STOCK |

| YJ | Late arrival of booked inward train-crew (where the inward and outward trains worked by that train-crew are operated under the same Track Access Contract) | INWD CREW |

| YL | Waiting passenger connections within connections policy, contingency plan or otherwise agreed by NR/TOC | AUTHSD CON |

| YM | Special stop orders within the contingency plan or agreed by NR/TOC | AUTHSD SSO |

| YN | Service Recovery- booked train crew, not available | FIND CREW |

| YO | Waiting platform/station congestion/platform alteration | PLATFORM |

| YP | Delays due to diversions from booked route or line | DIVERSION |

| YQ | Passenger overcrowding caused by a train being of short-formation | SHRT FRMD |

| YR | Tactical cancellation for service recovery not caused by late running | SR CNCL |

| YU | Service Recovery- booked rolling stock, not available | UNIT SWAPS |

| YT | Reactionary delay to a train that is not leaving the network, by a train that is leaving the network | NON NR INF |

| YX | Passenger overcrowding caused by delay or cancellation of another train or its own late running | OVER CRWD |

| ZS | No cause ascertainable for a Sub Threshold Delay causing Threshold Reactionary (where agreed by both Parties) | NOCAUSE AS |

| ZU | No Cause Identified After Full Investigation by Both Parties (A ‘Full Investigation’ will be one including all avenues of investigation agreed as reasonable by both Parties) | NOCAUSE ID |

| ZW | Uninvestigated Cancellations System Roll-Ups only | SYS CANC |

| ZX | Uninvestigated Late Start System Roll-Ups only | SYS L-STRT |

| ZY | Uninvestigated Station Overtime System Roll-Up only | SYS OTIME |

| ZZ | Uninvestigated Loss in Running System Roll-Up only | SYS LIR |

| Network Rail Open Data Feeds | |

|---|---|

| Data Feeds | About the Feeds • Account States • Durable Subscriptions • Example Code ( PHP / C# / Java / Ruby / Node.js) • Advanced Uses • FAQ • Release Notes |

| RTPPM | RTPPM Feed |

| Train Movements | Train Movements Feed • Train Activation • Train Cancellation • Train Movement • Train Reinstatement • Change of Origin • Change of Identity • Change of Location • TSPEED Field • Planned Cancellations • Cancellation Codes |

| TD | TD Feed • C-Class Messages • S-Class Messages • Train Describers • TD Berths |

| VSTP | VSTP Feed |

| TSR | TSR Feed • Route Codes |

| SCHEDULE | SCHEDULE Feed • Schedule and Location Records • Association Records • CIF Codes • How Scheduling Works • Allowances |

| Reference Data | Reference Data Feed • TOC Codes • CIF Codes • Delay Attribution Codes • Identifying Locations (STANOX, TIPLOC, NLC and 3-Alpha Codes) • STANOX Geographical Areas • Train Planning data |

Is Manual Machining Faster than CNC for Simple Parts?

CNCCookbook’s G-Code Tutorial

G-Code Tool Changes

Most CNC g-code programs will have one or more g-code tool changes programmed into them. This will be true even if your machine doesn’t have an automatic tool changer. That’s because the tool change programming serves two purposes. First, in the case of a machine with an automatic tool changer (ATC), the tool changing g-codes tell the ATC to load a particular tool in the spindle or, in the case of a lathe, to rotate that tool into position on the lathe’s turret. The second role of these codes is to set up a different tool length offset. The tool length offset tells the CNC machine how much the length of the current tool differs from tool #1. It will adjust its notion of where the tool tip is when you make your next move based on this.

Accomplishing these two functions can require anywhere from one to several g-codes. Let’s go through each possible g-code and it’s style of use.

T Tool Select and M06 Tool Change

The “T” word is commonly used to select a tool. On a VMC with ATC, usually the “T” word tells the mill to select that tool, but it requires the M06 word to be executed before the tool is actually changed. This gives the ATC a little bit of advanced warning, allowing it to rotate the new tool into position while the machine is busy doing something else, which can make for a faster tool change. On most lathes, and even for some mills, the M06 is not needed. On those machines, it is likely an error to use an M06.

Sample tool change using T + M06

N10 T12 ( Select Tool #12 )

N20 M06 ( Change to selected tool )

If the machine doesn’t use M06, the sample would look like this:

N10 T12

If you wanted to take advantage of the separate T and M06 to give your machine maximum time to get ready in order to make the tool change faster, you’d do something like this:

T12

M06

T14

(Machining with T12 in spindle, but T14 is ready for next M06)

M06

(Now T14 is loaded)

Atc Slot Delay Codes Ro Ghoul

T02 (Setting up T02 for later)

(Machining with T14)

M06

(Now T02 is in spindle)

( etc. )

Random Memory Tool Selection

One trick some machines use to make tool changes go even faster is to set it up so tools don’t have to go back into a particular pocket on the changer. Instead, the machine just sticks the tool in the nearest pocket so it doesn’t have to take so long to rotate a pocket into position. The machine keeps track of which slot T02 is actually in, for example, and you can always refer to it as “T02”

no matter what slot it winds up in.

Tool Offsets: Geometry and Wear Offsets

Now what about that business of selecting a Tool Offset so the machine knows how long the tool is?

First thing to note is that there are actually 2 different length offsets–the Geometry Offset and the Wear Offset. The Geometry offset is associated with each tool by number and is the one that grossly determines tool length. The Wear Offset is a fine tuning change to the overall tool length that is used to compensate for wear and to give the machinist the ability to fine tune what’s happening from part to part. For example, you may be turning a part to diameter and discover that after measuring the diameter with a micrometer it is slightly off. Perhaps it is 0.0013″ too large. To correct, you can enter a wear offset of -0.0013 to cause the machine to come out much closer to the desired tolerance.

Let’s ignore the Wear Offset for the moment. When you do your tool change, your machine controller will automatically apply the Geometry Offset based on the information contained in its tool table about each tool.

Fanuc-Style Combined Tool Number and Offset for Turning

Now that we know about these offsets, let’s take a look at specifying a toolchange on a lathe using Fanuc’s syntax. It’s pretty simple. To select tool #2, we’d use:

Atc Slot Delay Codes Redeem

T0202

“Why is the “02” repeated twice?” you wonder. That second “02” can be any 2-digits, and it selects the wear offset to use. By convention, most programs make the wear offset the same as the tool number so you don’t have to worry about matching them up.

G-Wizard Editor/Simulator Tool Change and Offset Post Options

This is all pretty simple to set up in the G-Wizard Editor / Simulator’s Post Options:

You have the ability to specify the range of T#’s as well as how many digits at the end of the T# are used to specify the offset.

Exercises

1. Get out your CNC controller manual and set up GWE to match your control’s way of doing Tool Changes.

2. Write a sample g-code program containing a tool change and verify during GWE playback that the tool was changed.

Atc Slot Delay Codes 2020

3. For some extra credit, check out our 2-part article on Tool Data Management and start thinking about how you will manage your tool data.